Les presses mécaniques à double montant de la série PMF sont adaptées à une large gamme d’applications dans des industries telles que l’automobile, l’aérospatiale, le ferroviaire et bien d’autres encore liées à la formage des métaux. Ce sont des presses à double réduction avec une ou deux bielles. Elles sont construites en acier S355JR, stabilisées et usinées à la fin du processus de soudage pour garantir un parallélisme et une précision parfaits. Conçues et calculées avec un logiciel par éléments finis, nous garantissons toujours nos normes élevées de précision et de qualité.

La bielle est construite en acier forgé à haute résistance avec des bagues en alliage haute performance.

Pour garantir un entretien et un fonctionnement parfaits, toute notre gamme est équipée d’un système de lubrification centralisé automatique avec un système progressif programmable.

Conçues avec un système complexe d’engrenages excentriques à rotation opposée qui permet une double réduction de la vitesse et de grandes longueurs de course. Une énergie élevée est également obtenue à des vitesses nominales très basses, adaptées aux opérations d’emboutissage.

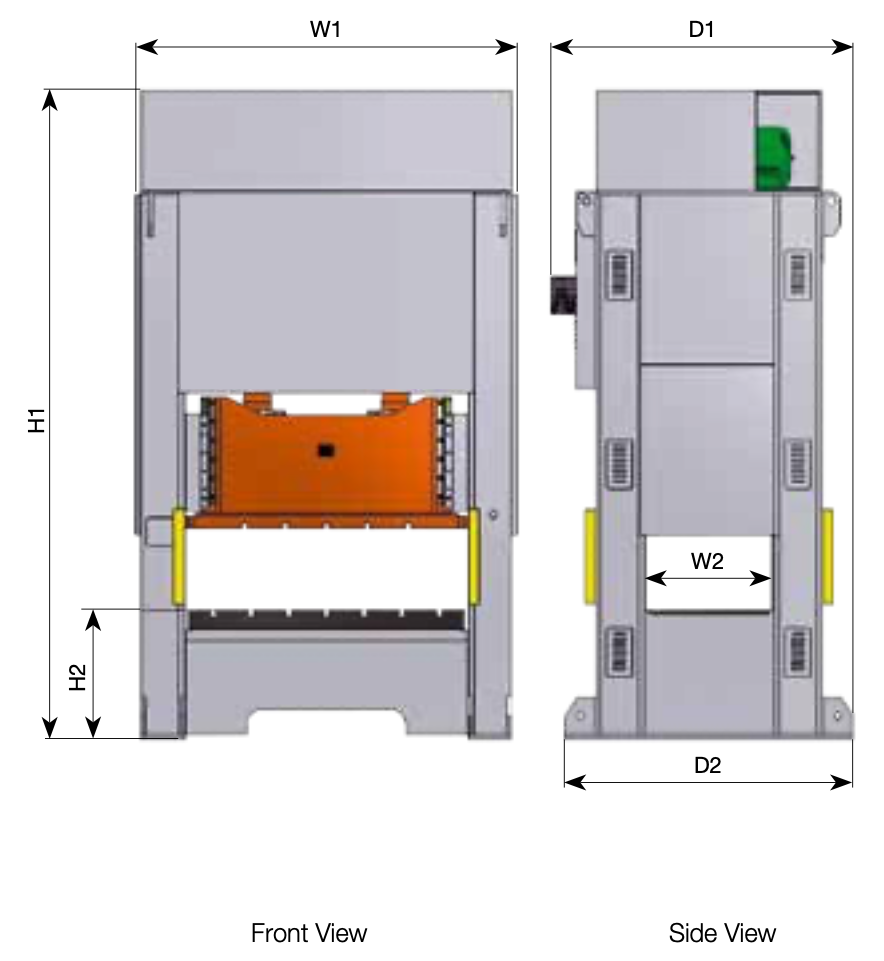

Les dimensions des hauteurs des guides prismatiques et des surfaces de glissement sont conçues pour offrir une rigidité maximale sous des exigences élevées, limitant la déformation des surfaces de travail à des valeurs minimales.

Le coulisseau a 6 guides prismatiques. Ils sont à double réduction avec des bielles doubles, une course fixe et de grandes tables.

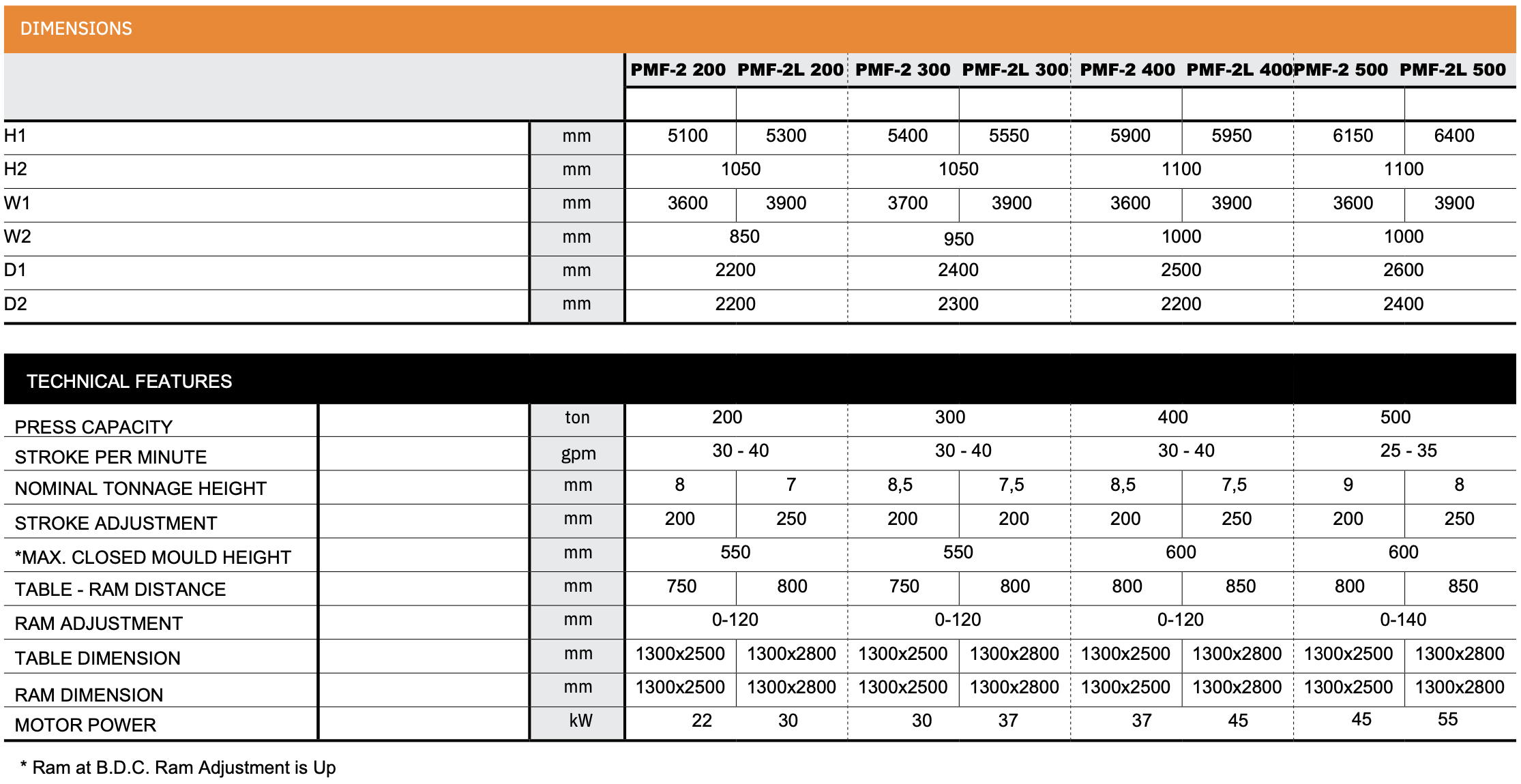

Disponibles avec une puissance allant de 300 à 630 tonnes.

SURCHARGE ET COMPENSATION

Il est équipé d’une unité de protection contre les surcharges qui protège les composants de la machine et les outils installés. Une valve de sécurité décharge l’huile de la chambre lorsque, pour une raison quelconque, la valeur définie, qui est supérieure à la charge nominale, est atteinte.

Pour un équilibrage efficace du coulisseau et des matrices, la compensation est assurée par deux cylindres pneumatiques.

EMBRAYAGE - FREIN

L’embrayage-frein est actionné électropneumatiquement, équipé d’une électrovanne de sécurité à double corps et de flux entrecroisés.

Le système pneumatique comprend un réservoir de compensation, un filtre régulateur-lubrificateur, un pressostat de contrôle et une valve de sécurité

INSTALLATION ÉLECTRIQUE ET SÉCURITÉ

Le tableau électrique comprend un sélecteur qui permet de choisir le type de travail à réaliser en mode manuel, semi-automatique ou automatique. Les opérations électriques et pneumatiques sont redondantes et autocontrôlées. Ils intègrent un PLC supplémentaire pour la manœuvre et la sécurité.

L’actionnement se fait par un bouton poussoir à deux mains et une pédale électrique basse tension.

Pour garantir la sécurité, ils intègrent des protections latérales praticables avec des barrières photoélectriques de catégorie IV situées sur les côtés de la zone de travail.

CARACTÉRISTIQUES

- Embrayage pneumatique

- Valve de sécurité double

- Commande à deux mains

- Commande par pédale électrique

- Lubrification centralisée automatique

- Engrenages baignés d’huile

- Réglage automatique du coulisseau

- Indicateur de hauteur de fermeture

- Capteur de limite de came mécanique

- Capteur de limite de came magnétique

- Variateur de vitesse

- PLC programmable (automate)

- Écran tactile

- Barrières photoélectriques avant et arrière

- Protecteur hydraulique de surcharge

- Support de sécurité

- Panneau suspendu articulé

- Équilibreurs pneumatiques

- Plaques anti-vibrations

- Garantie de 2 ans (*)

ACCESSOIRES OPTIONNELS

- Variateur de vitesse.

- Éjecteur ou coussin pneumatique ou hydraulique.

- Table inférieure auxiliaire.

- Système de changement rapide de matrice.

- Contrôle numérique de la force.