WORKSHOP HYDRAULIC PRESSES

The S Series double-column motorized hydraulic press from Hidrogarne is designed with a range of four different power capacities, from 80 to 200 tons. The double-column hydraulic press is specially designed for tasks such as extraction, threading, straightening, etc.

The S Series double-column hydraulic presses operate at a maximum hydraulic pressure of 320 BAR to ensure greater durability of the entire hydraulic system.

STRUCTURE

The S Series double-column hydraulic presses consist of a welded structure with four columns and open sides.

The double-column hydraulic press features a movable bed that can be positioned at different heights. It is secured with two pins located at the bottom of the bed. The lifting and lowering system uses chains operated by the press cylinder. It includes two machined support blocks.

We differentiate between two models:

- Double-column hydraulic press SD Models: These have a fixed head.

- Double-column hydraulic press SL Models: These have a laterally movable head equipped with a manual locking system. Movement is via bearings.

CYLINDER AND HYDRAULIC UNIT

Double-acting cylinder with chromed piston and maintenance-free wear-resistant guides. It is equipped with a removable and interchangeable pad to prevent piston damage.

Single-speed motorized hydraulic unit.

Glycerine-filled pressure gauge with reading in tons.

Cylinder operation via lever-operated hydraulic distributor.

ELECTRIC INSTALATION AND SAFETY

Electrical installation equipped with a motor guard and emergency stop.

Meets and satisfies all essential safety and health requirements according to CE regulations.

Supplied with an instruction manual.

TECHNICAL FEATURES

| MODEL | SD-80 | SD-100 | SD-150 | SD-200 | |

|---|---|---|---|---|---|

| Power | t | 80 | 100 | 150 | 200 |

| Motor power | kw | 3 | 3 | 4 | 5,5 |

| Piston stroke | mm | 250 | 250 | 250 | 250 |

| Maximum pressure | bar | 320 | 320 | 320 | 350 |

| Working speed | mm/s | 3,8 | 3,1 | 3.1 | 3.1 |

| Return speed | mm/s | 4,7 | 4,1 | 4 | 4,8 |

| Headstock displacement | mm | – | – | – | – |

| Frontal light | mm | 1050 | 1050 | 1050 | 1050 |

| Lateral light | mm | 210 | 230 | 290 | 290 |

| Max. vertical light | mm | 1020 | 1020 | 860 | 815 |

| Bed light | mm | 255 | 285 | 355 | 355 |

| Total front | mm | 1530 | 1595 | 1660 | 1660 |

| Total lateral | mm | 980 | 980 | 1180 | 1180 |

| Total height | mm | 2275 | 2315 | 2405 | 2470 |

| Weight | kg | 690 | 930 | 1500 | 1875 |

| MODEL | SL-100 | SL-150 | SL-200 | |

|---|---|---|---|---|

| Poer | t | 100 | 150 | 200 |

| Motor Power | kw | 3 | 4 | 5,5 |

| Piston Stroke | mm | 250 | 250 | 250 |

| Maximum Pressure | bar | 320 | 320 | 350 |

| Working speed | mm/s | 3,1 | 3.1 | 3.1 |

| Return Speed | mm/s | 4,1 | 4 | 4,8 |

| Headstock displacement | mm | 1050 | 1000 | 1000 |

| Frontal light | mm | 1500 | 1500 | 1500 |

| Lateral light | mm | 280 | 340 | 340 |

| Max. Vertical light | mm | 960 | 955 | 915 |

| Bed light | mm | 345 | 405 | 405 |

| Total front | mm | 2090 | 2150 | 2150 |

| total lateral | mm | 1180 | 1180 | 1180 |

| Total height | mm | 2660 | 2805 | 2855 |

| Weight | kg | 1830 | 2350 | 2620 |

OPTIONAL ACCESSORIES

- Manual elevation table equipped with manual spiral crown reducer.

- Hydraulic unit with two speed.

- Front pressure regulator.

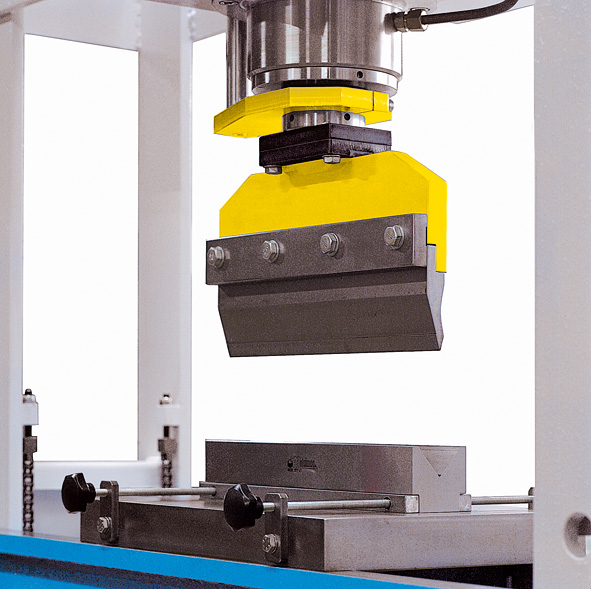

- 415 mm long folding tools set. Promecam clamping system.

- Additional manual pump with one speed, it allows two kind of operation manual and motorized.

- Anti-turning for the cylinder.

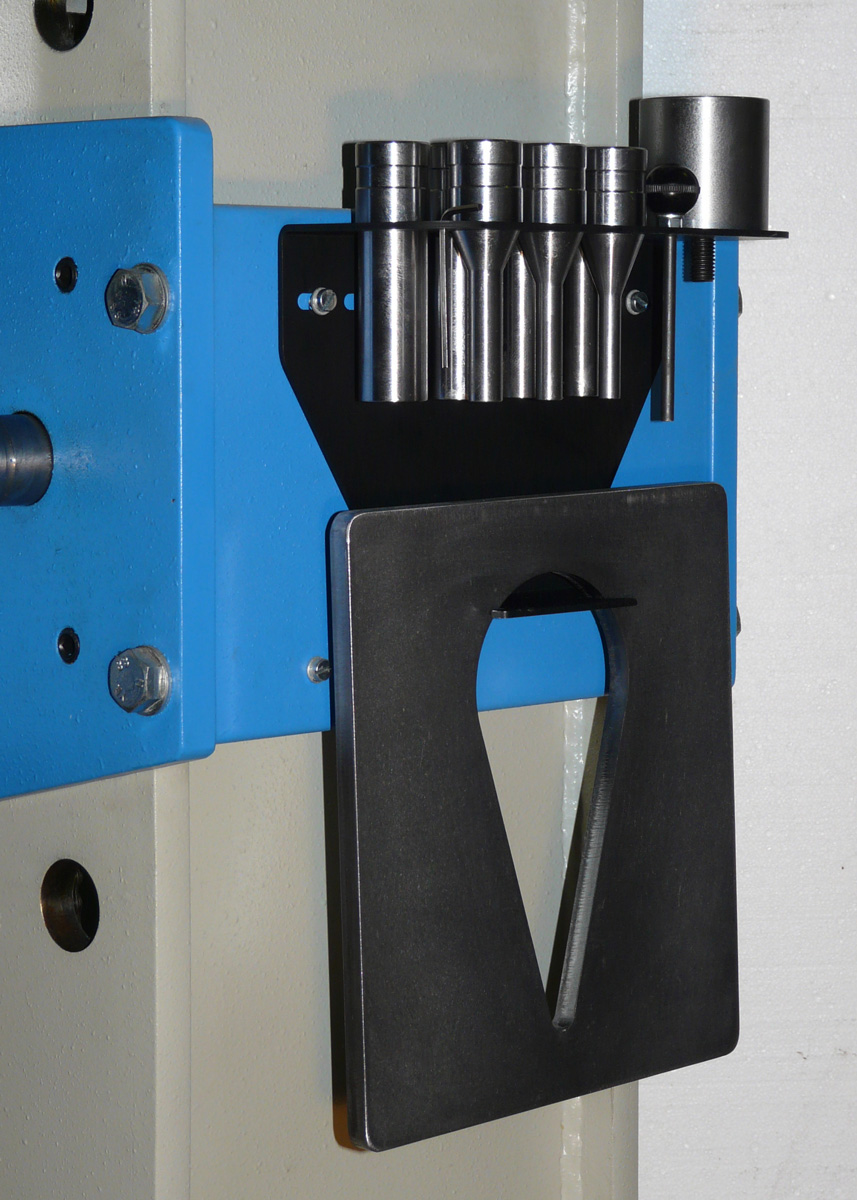

- Set of 7 pushers with adapter and plate (Ø 10-12-15-17-20-25-30 mm)

- Set of “V” blocks.