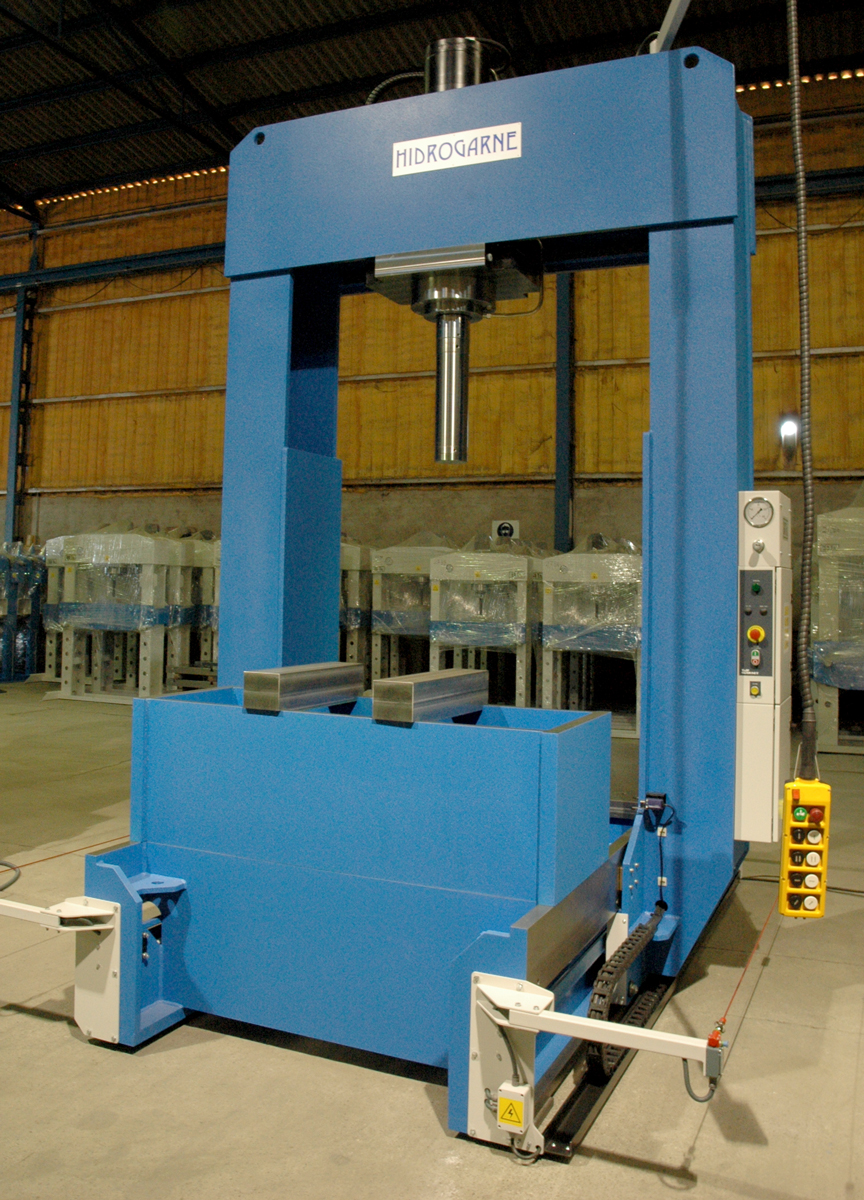

MOBILE GANTRY HYDRAULIC PRESSES WITH MOVABLE HEAD

We have designed motorized hydraulic presses with movable gantry and adjustable head from the T/NC series, offering a range of three different powers ranging from 150 to 300 tons.

Specifically designed for straightening welded structures and oxyfuel-cut plates.

Their design facilitates loading and unloading of large-volume pieces, plates, or structures. It allows access to different pressing points without the need to move the piece, thanks to the lateral displacement of the cylinder and the longitudinal movement of the gantry.

They operate with a hydraulic pressure of less than 320 BAR to ensure greater durability of the entire hydraulic system.

STRUCTURE AND TABLES

The hydraulic presses of the T/NC series consist of an electro-welded structure made exclusively of S355JR steel. It is stabilized and machined at the end of the welding process to ensure perfect parallelism and precision. Calculated and designed with finite element software. With all this, we always guarantee our high standards of precision and quality.

The longitudinal displacement of the gantry is carried out by a frequency converter and driven by a toothed belt. The lateral displacement of the head is motorized and, in the 220 and 300 ton models, is controlled by a frequency converter.

CYLINDER AND HYDRAULIC GROUP

Double-acting cylinder with seamless cold-drawn tube, chrome-plated piston, and maintenance-free wear-resistant guides. It is equipped with a detachable and interchangeable pad to prevent piston damage and machined at the end to adapt tooling.

Motorized hydraulic group with two-speed drive with automatic disconnection of the fast speed. Includes cylinder decompression valve.

ELECTRICAL INSTALLATION AND SAFETY

It incorporates a SIEMENS safety PLC model SIMATIC S7 1200 and a 4″ touchscreen model MTP-400 located at the electric box as standard. It allows programming the operating mode in semi-automatic and automatic, the power, the vertical stroke, and the dwell time of the upper cylinder. It has a storage capacity of 99 recipes, and all the aforementioned values can be programmed in each recipe.

Activation is carried out by a radio control pendant. It includes a double push button for slow or fast ascent and descent, emergency stop, and maneuver confirmation button.

To ensure safety, it incorporates a touch-sensitive safety edge device installed at the bottom of the gantry columns.

They are supplied with an instruction manual.

They comply with and meet all essential safety and health requirements according to CE regulations.

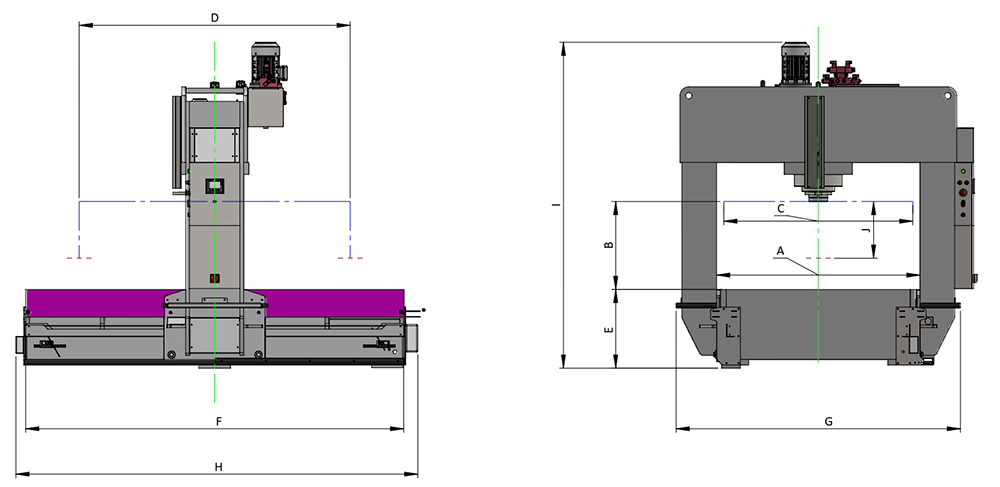

TECHNICAL FEATURES

| MODEL | TL-150/NC | TL-220/NC | TL-300/NC | |

|---|---|---|---|---|

| Power | t | 150 | 220 | 300 |

| Motor power | kw | 4 | 5.5 | 7.5 |

| Working speed | mm/s | 2 | 2.2 | 2 |

| Approaching speed | mm/s | 9.9 | 9 | 9.9 |

| Return speed | mm/s | 15.4 | 16.2 | 14.7 |

| Max press | bar | 315 | 315 | 315 |

| Piston stroke – J | mm | 450 | 450 | 450 |

| Lower table size | mm | 1550×3000 | 2045×3500 | 2545×4000 |

| Headstock movement – C | mm | 1100 | 1550 | 2000 |

| Bridge movement – D | mm | 2150 | 2500 | 3000 |

| Frontal light – A | mm | 1615 | 2060 | 2560 |

| Lateral light – B | mm | 700 | 700 | 700 |

| Working height – E | mm | 600 | 700 | 750 |

| Total front – G | mm | 2390 | 3300 | 3760 |

| Total lateral – H | mm | 3190 | 3630 | 4130 |

| Total height – I | mm | 2560 | 3005 | 3135 |

| Weight | kg | 6500 | 9400 | 13400 |

A. Front light B. Vertical light C. Head displacement D. Bridge displacement E. Working height G. Total Frontal Width H. Total Lateral I. Total height J. Piston stroke

OPTIONAL ACCESSORIES

- Lower table of 3000 x 1550 x 75 mm for TL-150

- Lower table of 3500 x 2040 x 85 mm for TL-220

- Lower table of 4000 x 2540 x 95 mm for TL-300

- 8 ejector cylinders installed on the lower table, 2 t each, for TL-150

- 12 ejector cylinders installed on the lower table, 2 t each, for TL-220/300

- Cylinder extender of 250 mm

- Industry 4.0

- Router for remote access

- Geometry adapted to your needs