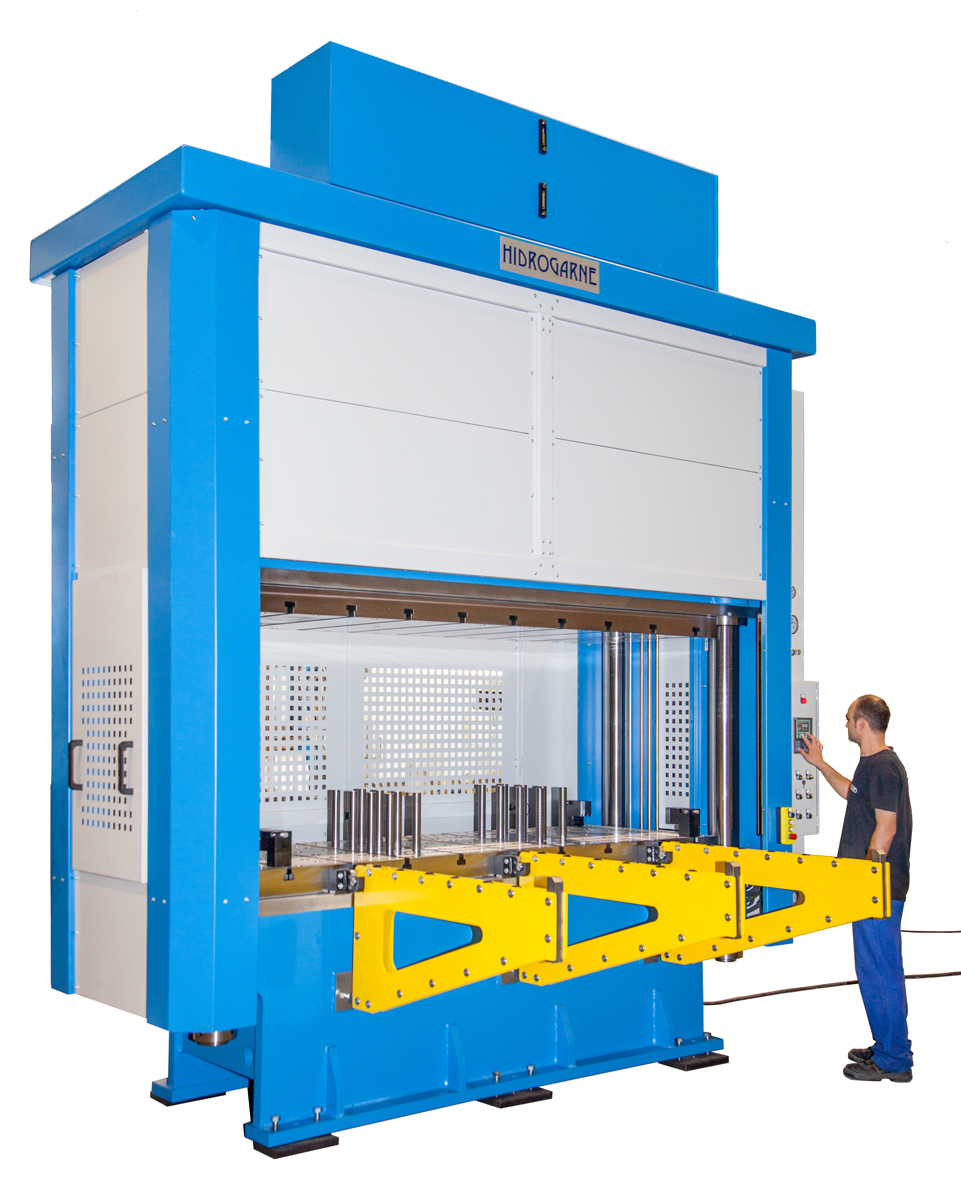

La presse hydraulique à quatre colonnes MV-250E/NC appartient à la série M/NC et est conçue sur mesure pour une plus grande précision et capacité, spécialement pour les travaux d’emboutissage profond.

Équipée d’une table supérieure et d’une table inférieure en acier C45E, usinées avec des rainures DIN-650 pour garantir une friction minimale dans le déplacement vertical de la table supérieure, facilitée par des manchons bimétalliques sans entretien et un parfait parallélisme assuré par quatre colonnes cylindriques chromées et rectifiées.

Elle utilise un système hydraulique optimisé avec une pression inférieure à 290 Bar, garantissant ainsi une durabilité et une fiabilité prolongées dans ses performances.

Elle respecte et satisfait toutes les exigences essentielles en matière de sécurité et de santé selon les normes CE.

PLUS D’INFORMATIONS

STRUCTURE ET TABLES

- Composée de trois blocs électrosoudés fabriqués exclusivement en acier S355JR.

- Stabilisée et usinée à la fin du processus de soudage pour garantir un parfait parallélisme et précision.

- Calculée et conçue avec des logiciels par éléments finis.

- La table inférieure est équipée d’un coussin hydraulique de 50 Tn avec une surface utile de 950 x 750 mm et trois consoles frontales pour soutenir la matrice à l’extérieur de la presse.

- Incorporation d’un NC SIEMENS KTP-400 pour la régulation de la course de la table supérieure, les changements de vitesse et la régulation du coussin.

- Incorporation d’un PLC SIEMENS S-7 permettant la programmation de 99 mémoires.

CYLINDRE ET GROUPE HYDRAULIQUE

- Cylindre simple effet avec chemise rodée, piston chromé et guides anti-usure.

- L’ensemble du groupe hydraulique est installé sur la partie supérieure de la presse.

- Le groupe hydraulique comprend une pompe hydraulique silencieuse de marque Denison et un refroidisseur air-huile.

- Comprend :

- système de décompression,

- valves solénoïdes de pression,

- valves de pré-remplissage,

- valve de communication,

- valve de retenue,

- valve de décharge de pression et

- valve anti-chute.

INSTALLATION ÉLECTRIQUE ET SÉCURITÉ

- Incorporation d’un PLC de sécurité SIEMENS modèle SIMATIC S7 1200 et d’un écran tactile de 4” modèle KTP-400 situé sur le panneau électrique. Permet de programmer le mode de fonctionnement en semi-automatique et automatique, la puissance, la course et le temps de maintien. Elle a une capacité de stockage de 99 recettes, chaque recette pouvant programmer toutes les valeurs précédentes.

- Le panneau électrique comprend un sélecteur permettant de choisir le type de travail à effectuer en mode manuel « Réglages » ou cycle automatique « Production ».

- Le fonctionnement de la machine se fait par pédales électriques basse tension.

- Pour garantir la sécurité, elle comprend des barrières photoélectriques de niveau IV situées dans la zone de travail frontale, deux protections latérales fixes et une protection ouvrable avec détecteur magnétique de déconnexion situé à l’arrière.

CARACTÉRISTIQUES TECHNIQUES

| MODÈLE | MV-250E/NC | |

| Puissance | tn | 250 |

| Puissance moteur | hp | 20 |

| Course du piston | mm | 500 |

| Vitesse d’approche | mm/s | 80 |

| Vitesse de travail | mm/s | 7 |

| Vitesse de retour | mm/s | 105 |

| Diamètre des guides | mm | 150 |

| Pression maximale | Bar | 260 |

| Surface utile des tables | mm | 2.500 x 1.150 |

| Entre les colonnes | mm | 2.500 x 700 |

| Hauteur verticale maximale | mm | 1.000 |

| Hauteur verticale minimale | mm | 500 |

| Surface de distribution du coussin | mm | 950 x 750 |

| Hauteur de travail | mm | 1.100 |

| Hauteur totale | mm | 3.650 |

| Poids | kg | 15.000 |